NoVOC video

Objectives and ambition

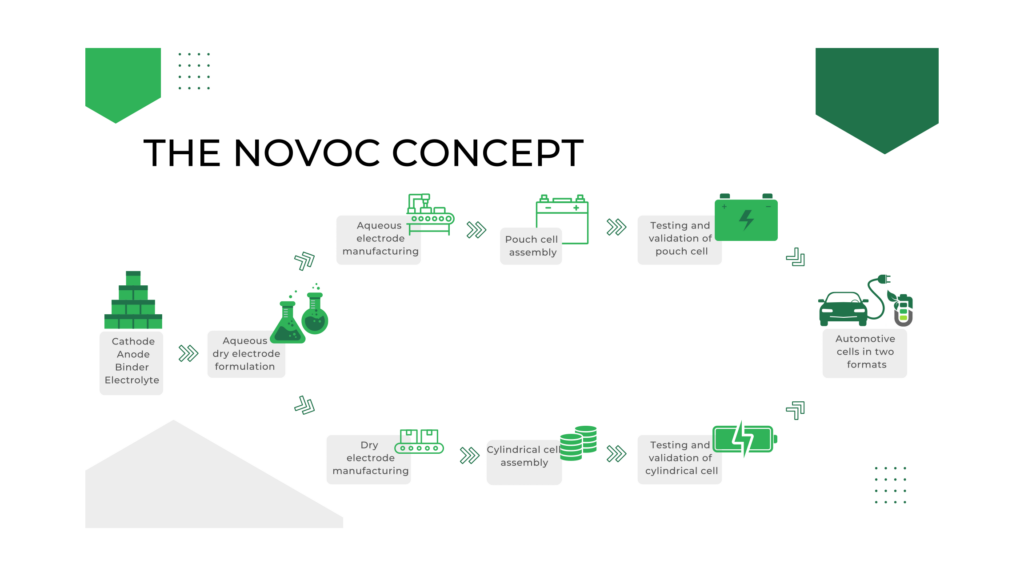

NoVOC aims to implement environmentally friendly, non-toxic lithium-ion battery (LIB) production at pilot scale. This includes manufacturing battery cell components, as well as designing and assembling cells. We use both aqueous and dry electrode manufacturing processes. This approach significantly decreases costs and environmental impact.

We are building a new strategic technology for competitive, low-cost, and eco-friendly LIBs. These batteries will be available in both cylindrical and pouch formats. They are intended for production in giga factories across Europe, especially for the fast-growing electromobility market.

Project concept and methodology

To solve the existing issues in current cell manufacturing processes, NoVOC introduces the following innovations to develop more sustainable cell manufacturing processes and, thus, lowcost cells for automotive applications:

- Aqueous processing of electrodes

- NoVOC dry processing of electrodes

- Cell manufacturing and testing

The innovative cell manufacturing processes proposed by NoVOC, namely aqueous cell manufacturing and dry cell manufacturing, assures no organic volatile compounds emission and demonstrates the viability of these processes by validating cell performance, cost and environmental benefits. Both methods will be optimized at a lab scale by R&D partners in close coordination with materials suppliers and then scaled up materials will be provided to industrial LIB manufacturing partners for a pilot-scale cell manufacturing.

Since the overall LIB industry is still exploring both cylindrical and pouch cell configurations, NoVOC will explore both architectures. The figure on the left shows the schematic representation of the whole project concept.

Impact

LIBs have high energy and power density and long cycle-life and naturally it has come to dominate the energy storage technology especially in portable electronics, and recently in electric vehicles and even as fixed grid storage. Although a few alternatives are being explored, LIBs are widely expected to continue their dramatic growth and the projected global demand is expected to double by 2030. In spite of its critical importance in present and future key technologies, today the global LIB manufacturing is dominated by the Asia-Pacific region and Europe’s share is presently about 2%, as LIB investiments in Europe are hindered by the high European standards of workplace exposure limits, emission limits and also the upcoming battery recycling regulations.

To bring Europe to the forefront in LIB manufacturing, therefore, new production methods are needed which are ‘future-proof’ in terms of safe and sustainable manufacturing. This would not only enable higher investment in production capacity, but also bring Europe to the forefront in cutting edge and safe production technologies for future LIBs. Furthermore, in light of the ambitious EU’s climate targets by 2050, nurturing emerging technologies are particularly needed, such as LIBs to enable zero-emission mobility and renewable energy storage.

The NoVOC project takes important steps towards zero emission mobility and to sustain the high standard of living in Europe with minimal impact to the health, environment, and global climate.